Call us on

1800-571-2244

E-mail us

info@foracepolymers.in

High Technology Long Life Die coats from John Winter Co. Ltd., U.K.

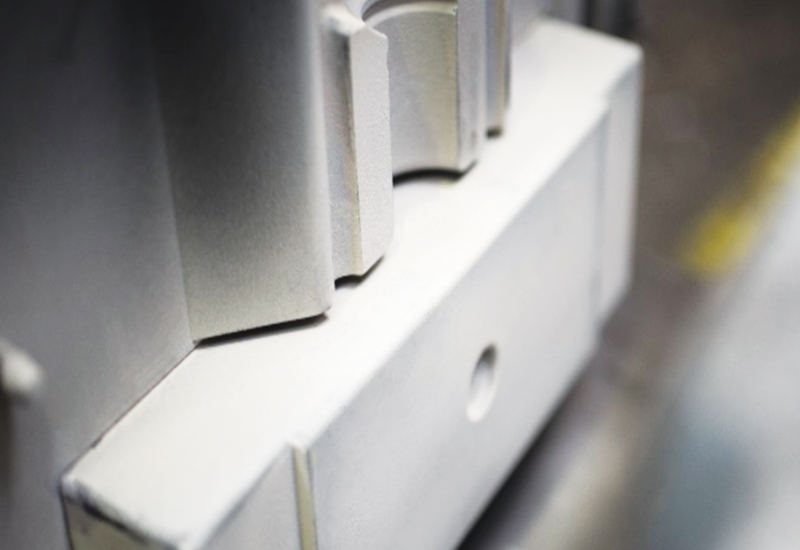

Home High Technology Long Life Die coats from John Winter Co. Ltd., U.K.Forace Polymers is an Exclusive Partner with M/s John Winters Co. Ltd., U.K. regarding their High technology Life Long Die coats for Indian market.

John Winter Dytek range of insulated coatings are specifically designed to

- Dytek range of insulated coatings are for use in low pressure and gravity die casting applications.

- Helps to increase productivity and reduce the downtime

- Give a “Longer Life” (LL) protection of the die – more shots per application

- Made from highly insulating refractory materials, bonded together with a higher heat resisting binder gives longer protection to the die from wear and erosion caused by repeated exposure to hot molten metal.

- Provide insulation enabling control of cooling and solidification – reduced porosity

- A range of coatings that can be used to insulate specific parts of the die to promote directional solidification.

- Lubricate enabling easier release of the casting from the die – less damage to die.

- In difficult cases Dytek G is specifically designed solid lubricant based costing to be applied on top of an insulating coating to ease release of the casting from the dye.

- Provide a smooth surface – producing a high quality surface finish

- Textured to enable enhanced metal flow reducing cold shuts and entrapped gas.

- Using an engineered blend of refractory and or insulating components of specific particle size creates the surface texture required for the specific customer application.

John Winter has multiple grades for various applications

| Sno. | Dytek | Application |

| 1 | S | High insulating smooth coating. |

| 2 | S LL | High insulating smooth coating with enhanced Long Life. |

| 3 | M | Textured Insulated coating designed to promote metal flow and reduce entrapped air. Ideal for the production of thin and flat surfaced castings. |

| 4 | G | Graphitic based coating used to enable release of the casting from the die. Designed to be applied on top of insulated coating. |

| 5 | T | Titanium Oxide coating produces a very smooth surfaces. Predominantly used in the production of alloy wheels on top die faces which produce the visible part of the wheel. |

| 6 | V | Highly insulating textured coating for the production of thin sectioned castings. |

| 7 | SI | Smooth Low-cost general-purpose coating. |

| 8 | D | Two part smooth insulating coating exhibiting excellent durability ideal for high volume general purpose castings. |

| 9 | Zr | Zircon / Red Iron oxide primer used to protect the dies and help with the adhesion of insulted top coating. The red colour enables visual confirmation when the top coating has worn. |

| 10 | Hardner | Used to increase bonding strength in cases of high dilution rates. |